Menene Sintered Metal?

Menene Ƙa'idar Aiki ta Sintered?

A takaice don faɗi, Saboda barga mai ƙarfi,sintered karfe tacesuna ɗaya daga cikin mafi kyawun abubuwan tacewa

a zamanin yau. Hakanan, babban zafin jiki na kayan ƙarfe, matsa lamba, da juriya na lalata zasu iya taimaka muku

cikin sauƙin kammala aikin tacewa a cikin yanayi mafi muni, Warewa da tace ƙazantar da ta wuce kima

ba kwa buƙatar ko taimaka muku fitar da iskar gas mafi girma ko ruwa don aikinku, kuma idan kuna neman

wasu masana'anta na gaske zuwa tace karfe na OEM don tsarin tacewa, da fatan za a duba nan don nemo

daManyan Masana'antu Tace Masu Kera.

Wataƙila bai kamata ku ji wannan kalmar da yawa a cikin rayuwar ku ta yau da kullun ba.

Amma a zamanin yau, karfen da aka yi da shi don yin amfani da shi a masana'antu daban-daban, karfe ya fara zama.

dakey fasaha a wasu masana'antu.

SannanAbin da yake daidai shine Ƙarfe na Sintered?

A zahiri, reshe ne na masana'antar ƙarfe na foda, a takaice, shine bakin karfe 316L.foda ta cikin mold

siffata, babban zafin jiki sintering cikin siffar da kuma aiki na wani tsari da muke bukata.

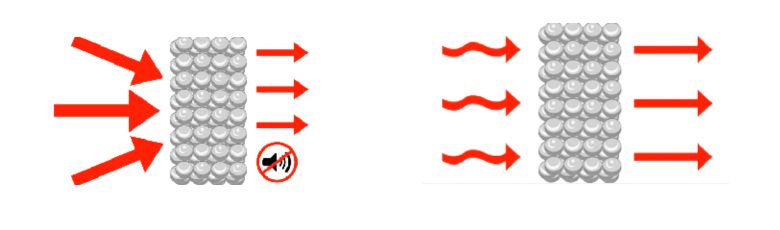

Sa'an nan, Na farko, an yi la'akari.Menene sintered?

Sintering shine tsarin ƙaddamarwada kuma kafa m taro naabu

ta zafi ko matsi ba tare da narka shi ba har ya kai ga ruwa. Sintering wani bangare ne natsarin masana'antu da aka yi amfani da shi

tare da karafa, yumbura,robobi, da sauran kayan.Wikipedia

Kamar yadda Wikipedia ya bayyana, ana iya haɗa nau'ikan kayan da yawa, kuma nau'ikan kayan da aka ƙera suna da

dabanaikace-aikace. Sannan a nan muna sodon yin magana game da ƙarin cikakkun bayanai game da ƙarfe na ƙarfe.

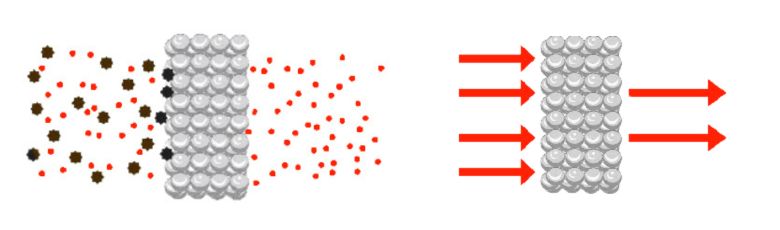

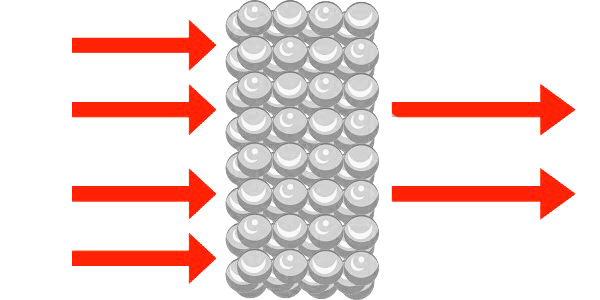

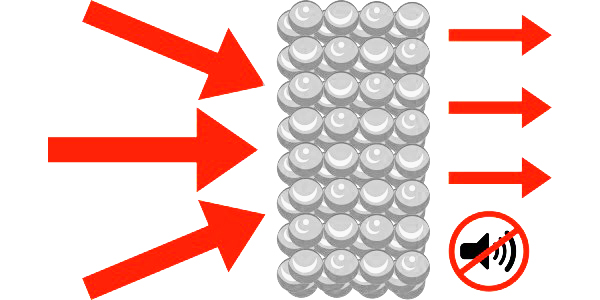

1. Tace da Rabuwa 2. Hana ruwa

3. Rage surutu 4. Tsagewar kwarara

TarihiAbubuwan da aka bayar na Sintering Metal

Wanene ya Ƙirƙirar ɓangarorin kuma ya fara amfani da samfuran da aka ƙera?

Bisa ga bayanan tarihi, tsarin ɓarkewar ya samo asali ne a lokacin juyin juya halin masana'antu na biyu na karni na 18

a Sweden da Denmark. An gano baƙin ƙarfe da aka dasa a lokacin aikin narke a cikin ma'adinan kwal. Amma har zuwa 1980, mutane

ya fara amfani da karfen da aka yi wa tace mai. Kuma don 1985, na farko ya yi amfani da fasahar tacewa ta HyPulse® don

ci gaba da slurry mai tacewa.

Don haka a zahiri, zaku iya bincika kamar haka, akwai babban lokacin haɓaka 3.

Don haka a zahiri, zaku iya bincika kamar haka, akwai babban lokacin haɓaka 3.

1.Tsohon Asalin

*Shekarun Tagulla:

Shaida ta farko na tsarin tafiyar hawainiya ta samo asali ne tun zamanin Bronze Age, inda abubuwan ƙarfe suke.

mai yiyuwa ne ta hanyar dumama da damfara foda na karfe.

* Shekarun ƙarfe:

Dabarun aikin ƙarfe, gami da yin amfani da tama mai zafi da matsawa, ƙila an haɗa su

abubuwa na sintering.

2.Juyin Juyin Masana'antu da Ci gaban Farko

*Karni na 19:

Juyin juya halin masana'antu ya ga ƙarin sha'awar dabarun aikin ƙarfe. Foda karfe,

wani precursor zuwa sintering, ya fara fitowa a matsayin hanya don samar da karfe abubuwa daga powdered kayan.

*Farkon Qarni na 20:

Ci gaban kimiyyar ƙarfe da kayan aiki sun haifar da ƙarin ci gaba a cikin fasahohin sintiri.

Samar da matatun ƙarfe mai ƙyalli da bearings ta amfani da matakan sintiri ya zama ruwan dare gama gari.

3. Zamani na Zamani da Ci gaban Fasaha

*Tsakiyar Karni na 20:

Fasahar sintering ta sami babban ci gaba a tsakiyar karni na 20, wanda ci gaba ya haifar

a foda metallurgy da kayan kimiyya. Ci gaban high-yi sintered kayan ga

sararin samaniya, motoci, da aikace-aikacen masana'antu sun zama abin mayar da hankali.

*Marigayi 20th da Farkon Karni na 21:

Ƙarshen ƙarni na 20 da farkon ƙarni na 21 sun shaida ci gaba da ƙirƙira a cikin fasahar sintering. Ci gaban

na ci-gaba fasahar sintering, irin su selective Laser sintering (SLS) da binder jetting, fadada kewayon.

na kayan aiki da rikitattun siffofi waɗanda za a iya samarwa.

Aikace-aikace na zamani

* Motoci:

Ana amfani da kayan da aka yi amfani da su sosai a cikin kayan aikin mota, gami da gears, bearings, da masu tacewa.

Kaddarorin su, kamar ƙarfi, karko, da porosity, sun sa su dace don buƙatar aikace-aikace.

*Aerospace:

Ana amfani da kayan da aka ƙera a cikin sassan sararin samaniya saboda nauyinsu mai sauƙi, ƙarfin ƙarfi.

Ana samun su a sassa kamar injin turbine, nozzles na mai, da masu musayar zafi.

*Na'urorin Likita:

Ana amfani da kayan da aka ƙera a cikin na'urorin likitanci iri-iri, waɗanda suka haɗa da dasa shuki, kayan aikin haɓaka, da abubuwan haƙori.

Kwatankwacinsu da kaddarorin da za a iya daidaita su sun sa su dace da waɗannan aikace-aikacen.

*Aikace-aikacen masana'antu:

Abubuwan da aka ƙera suna da aikace-aikacen masana'antu da yawa, gami da tacewa, lantarki, da ajiyar makamashi.

Ƙaƙƙarwar su da halayen aiki suna sa su daraja a cikin masana'antu da yawa.

Kammalawa

Ko ta yaya, fasahar Sintering ta samo asali sosai a cikin ƙarni, daga tsohuwar asalinta zuwa aikace-aikacenta na zamani.

Ta hanyar ci gaba da ci gaba a kimiyyar kayan aiki da tafiyar matakai na masana'antu, kayan da ba su da tushe sun zama

mahimman abubuwan da ke cikin masana'antu daban-daban, suna ba da gudummawa ga ci gaban fasaha da haɓakawa.

To menene Sintered Metal Filter?

Sauƙaƙan ma'anar tacewar ƙarfe ta sintered:

Tace karfe ce da ke amfani da barbashi na foda na karfegirman barbashida za a siffata da tambari.

high-zazzabi sintering tsari. Sintering shine tsari nakarfe ta amfani da foda-sizedjikinsu

daban-daban karafa da gami bayan stamping.

Metallurgy yana faruwa ta hanyar yaduwa a yanayin zafi da ke ƙasa da wurin narkewar tanderun zafin jiki.

Karfe da gamida aka saba amfani da shi a yausun hada da aluminum, jan karfe, nickel, bronze, bakin karfe,

da titanium.

Akwai matakai daban-daban da za ku iya amfani da su don samar da foda. Sun hada da nika, atomization,

da rugujewar sinadarai.

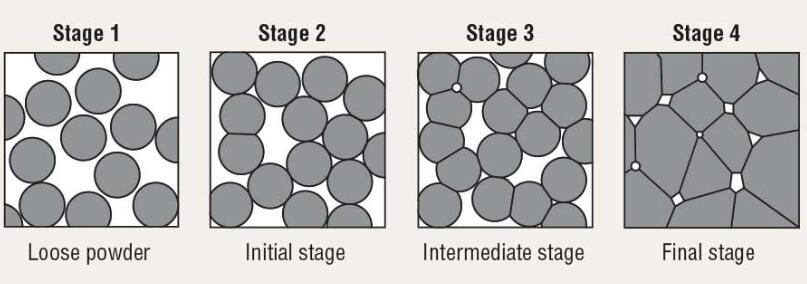

Abin da Sintering Tsarin Samar da Tacewar Karfe

Sa'an nan, don haka a nan, muna so mu duba aiwatar daki-daki na Metal tace masana'antu. idan kuna sha'awar, da fatan za a duba ƙasa:

1.) Menene Sintering, Me yasa Amfani da Sintering?

Simple definition sintering ne karfe foda an bonded tare da high zafin jiki da kuma sauran hanyoyin a ciki

tsarin da ake so.A cikin kewayon micron, babu iyakancewar jiki tsakanin ɓangarorin foda na ƙarfe,

wanda shine dalilin da ya sa za mu iya sarrafa nisan pore

ta hanyar samarwa.

Harsashi mai laushi na tsarin sintiri yana samar da tsayayyen siffar karfe kuma yana samarwa

kayan tare daaikin tacewa mai ƙarfi.

2.)3-MainMatakan Samar da Tacewar Karfe na Sintered

A: Mataki na farko shine Samun Karfe na Wuta.

The karfe foda, Za ka iya samun karfe foda ta nika, atomization, ko sunadarai bazuwar.

Kuna iya haɗa karfe ɗayafoda tare da wani karfe don samar da gami yayin aikin ƙirƙira,

ko kuma kuna iya amfani da foda ɗaya kawai. Amfanin sintering shinebaya canza jiki

Properties na karfe abu. Tsarin yana da sauƙi don haka abubuwan ƙarfe ba su canza ba.

B: Tambari

Mataki na biyu shine zuba foda na karfe a cikin wani tsari da aka riga aka shirya wanda za ku iya siffanta tacewa.

An kafa taron tacewa a dakizafin jiki da kuma ƙarƙashin stamping. Adadin matsa lamba

ya danganta ne da karfen da kuke amfani da shi, domin karafa daban-daban suna da nau'in elasticity daban-daban.

Bayan babban tasiri mai mahimmanci, an haɗa foda na ƙarfe a cikin ƙirar don samar da tace mai ƙarfi.Bayan da

high-matsi tasiri hanya, za ka iyasanya tace karfe da aka shirya a cikin tanderu mai zafi mai zafi.

C: Tsananin zafin jiki mai girma

A cikin aikin sintiri, ana haɗa ƙwayoyin ƙarfe don samar da raka'a ɗaya ba tare da isa wurin narkewa ba.

Wannan monolith yana da ƙarfi sosai,m, da porous tace kamar karfe.

Kuna iya sarrafa porosity na tacewa ta hanyar aiwatarwa gwargwadon yanayin kwararar iska ko ruwa don tacewa.

Nadi madaidaicin matakin kafofin watsa labarai yana daidai da madaidaicin huɗar ƙura, ko matsakaicin girman pore na tacewa.

Sintered karfe kafofin watsa labarai newanda aka bayar a maki 0.1, 0.2, 0.5, 1, 2, 5, 10, 20, 40 and 100. Ma'aunin tacewa a cikin

ruwa don maki mai jarida 0.2 zuwa 20 yana tsakanin 1.4 da 35 µmcikakke. Ƙimar tacewa a cikin kewayon gas

daga 0.1 zuwa 100 µm cikakke.

Me yasa ake amfani da Sintering Karfe don yin Tace?

Wannan tambaya ce mai kyau, me yasa ake amfani da karfe don yin tacewa?

Amsar ita ce mai sauƙi, kuma ko da yake akwai dalilai da yawa, farashi shine mafi mahimmanci.

Me yasa Kudin ?

Haka ne, karfen da aka ƙera yana da tsayayyen tsari kuma ana iya sake amfani da shi, mai tsabta, da kuma amfani da shi sau da yawa.

Haka kuma, karafa daban-daban suna da tsayayye na zahiri da sinadarai kuma ba sa lalacewa cikin sauƙi.

Shi ya sa ake amfani da Filters da yawa a masana'antu daban-daban.

Menene Zaɓuɓɓukan Material donTace masu tsauri?

Tare da ci gaba da ci gaban fasahar ƙarfe na foda, akwai ƙarin zaɓi na

kayan don sintered metal filters,

Kuna iya zaɓar daga wasu karafa da ƙari da yawa don saduwa da buƙatun musamman na mafi girma

zazzabi da matsa lamba, lalatajuriya da dai sauransu, Babban karfe kayan kamar:

-

Tace Bakin Karfe; 316L, 304L, 310, 347 da 430

-

Tagulla

-

Inconel® 600, 625 da 690

-

Nickel200 da Monel® 400 (70 Ni-30 Cu)

-

Titanium

-

Alloys

Tsarkakewabakin karfe tace, gami da harsashin tacewa, faranti, da bututun da aka yi daga bakin karfe

304 da 316, suna ba da ingantaccen tacewa, tsawon rayuwar sabis, da juzu'i a cikin aikace-aikacen ruwa biyu

da tace gas. Suna aiki da kyau a cikin yanayin zafi mai zafi da lalata.

Za a yi amfani da ƙarfe da yawa a nan gaba.

8-Babban Amfanin Tacewar Karfe na Sintered Metal

1. ) Juriya na lalata

Yawancin karafa suna da juriya ga lalata, kamar sulfides, hydrides, oxidation, da sauransu.

2. ) Mafi inganci kawar da gurɓataccen abu

Daidaita porosity na harsashi zuwa ruwa yana nufin za ku iya cimma cikakke

tacewa kana so ka samu aruwa mara gurbatawa. Shima tunda tace bata fasa ba.

Tace batasan halin da take ciki bana gurɓatattun abubuwa a cikin ruwa.

3. ) Babban Girgizar Ruwa

A lokacin aikin masana'antu, ana haifar da zafi mai zafi, da kuma abubuwan da ke cikin jiki

waɗannan karafa suna taimakawa shaTace babban zafin zafi. A sakamakon haka, zaka iya amfani da waɗannan

tacewa a cikin kewayon aikace-aikace dangane dakewayon thermal na aikace-aikacen.

Babban girgizar zafi kuma yana tabbatar da tace ruwa mai inganci ba tare da damuwa ba

zafin aikace-aikacen.

4.) Matsalolin Matsi Mai Ma'ana

Asintered karfe tacezai iya kiyaye matsa lamba a cikin aikace-aikacenku, don haka tabbatarwa

matsakaicin aiki.

Ƙarar matsa lamba na iya cutar da aikace-aikacen ku.

5. ) Zazzabi da Ƙarfin Ƙarfafawa

Kuna iya amfani da wannan tacewa a aikace-aikace tare da yanayin zafi da matsa lamba ba tare da

damu da abinda tace.

Yin amfani da matatun ƙarfe na sintered a cikin tsarin samar da halayen sinadarai da gas

tsire-tsire masu magani suna tabbatar da kusami mafi kyawun sakamakon tacewa.

6. ) Tauri da Juriya ga Karyewa

Wani fa'idar yin amfani da matatar ƙarfe mai tsauri shine cewa yana da ƙarfi da juriya

karaya.

A lokacin aikin masana'antu, haɗin gwiwar karafa yana faruwa a yanayin zafi da kyau

a ƙasa da wurin narkewa.

Samfurin da aka samu shine taurin ƙarfe mai tauri wanda zai iya jure iri-iri

m yanayi.

Misali, zaku iya amfani da shi a aikace-aikacen da ke buƙatar juzu'i ba tare da tsoron karyewa ba.

7.) Hakuri mai kyau

Haƙuri mai kyau yana nufin cewa matatun ƙarfe na ku na iya tace ruwan ku ba tare da amsawa ba.

Da zarar tacewar ku ta cika, tacewar ƙarfen da aka ƙera za ta riƙe kayanta na zahiri.

Koyaya, zai taimaka idan kun tabbatar cewa ƙarfen da kuka zaɓa don tacewa ba zai yi ba

amsa da ruwan da kuke tacewa

8.) Kewayon Matsalolin Geometric

Sintered cartridges suna ba ku damar jin daɗin zaɓuɓɓuka masu yawa na geometric. Kuna iya cimmawa

wannan yayin saka fodaa cikin rini a lokacin masana'anta.

Samfurin shine wanda yakamata ya tsara tacewa.

Don haka, kuna da 'yanci don sarrafa ƙirar bisa ga ƙayyadaddun ku.

Misali, idan aikace-aikacenku yana buƙatar ƙaramin tacewa, zaku iya sarrafa ƙirar cikin sauƙi

don samun ƙarami

sintered karfe tace.Hakanan, idan aikace-aikacenku yana da ƙira na musamman, kuna iya sauƙi

sarrafa zane a cikinmold a lokacin masana'antu.

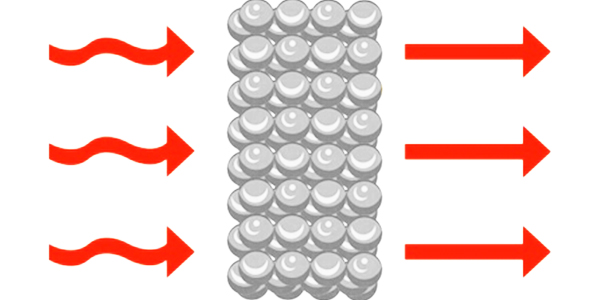

Yaya Sintered Metal Filters Aiki?

Wannan matsalar kuma za a iya cewa ita ce ka'idar aiki na matatun ƙarfe da aka yi wa sikirin. Mutane da yawa suna tunani

cewa wannan tambaya ita ceda wuyar amsawa, kuma ba haka bane.Kuna iya mamakin wannan, amma watakila ku

ba zai kasance bayan karanta bayanina ba.

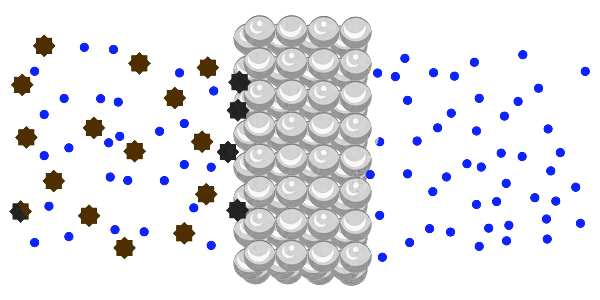

Matsalolin ƙarfe da aka ƙera suna da amfani sosai. Tarin gurɓataccen abu yana faruwa a saman

ruwa; lokacin daruwa ya ratsa ta karfe tace, damanyan barbashi da gurɓatawa za su kasance

hagu a gefe guda na harsashi, amma lokacinzabar ingantaccen matakin tacewa don ruwan ku, ku

bukatar tabbatar da hakanyana iya ma tace abubuwan da ake bukata.

*Wadannan Abubuwan Bukatu Sun Haɗa

1. Karɓar Riƙewa Ƙarfin Wankin Baya

2. Rage Matsi

Don sauke matsa lamba, kuna buƙatar la'akari da abubuwa da yawa.

Wadannan abubuwan sun hada da

ADankowar ruwa, saurin ruwa yayin da yake gudana ta bangaren tacewa, da halaye masu gurɓatawa.

BHalayen gurɓatawa sun haɗa da sifar barbashi, yawa, da girma.

Idan gurɓataccen abu yana da wuya kuma na yau da kullum a cikin siffar, samar da cake mai yawa, to, tacewa saman ya dace.

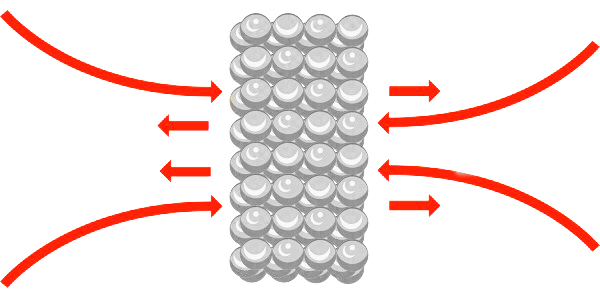

*Ingantacciyar Tacewar Karfe Na Sintered Ya Dogara

1.Ƙaƙƙarwar matsa lamba yana saukowa zuwa wurin da cikakken matsa lamba ya kai.

2. yawan kwararar ruwan.

Kuna iya cimma yanayi na ƙarshe ta hanyar kauri mai gurɓatacce wanda ke ƙaruwa zuwa inda matsa lamba na ruwa ya faɗi.

Wannan matsa lamba yana faɗuwa ci gaba har sai an kai matsakaicin faɗuwar ɗanko da ake buƙata.

Wani lamari mai mahimmanci shine wankewar baya na tacewa, wanda aka yi ta hanyar matsawa gas zuwa allon da sauri

buɗe bawul ɗin fitarwa na bayakamar yadda wankin baya ke faruwa.

Babban bambancin matsa lamba mai girma shinehalitta. Yana kawar da gurɓataccen abu daga tacewa yadda ya kamata

element surface. A bayakwararar ruwa mai tsafta ta bangaren tacewa yana kawar da gurbatattun abubuwa kuma yana jagorantar su

fita tace.

Tsayayyen tashin matsa lamba yana nuna daidaitaccen rarraba girman gurɓataccen abu.To

cimma daidaitoaiki, dole ne ku tabbatar da cewa raguwar matsi na kashi na tace ya tabbata.Idan yanayin zafi

na canza ruwa, yana tasiridankowar ruwan. A wannan yanayin, matsa lamba yana raguwa a fadin tacekashi zai

karuwa kuma ba cimma tasirin tacewa ba.

Sabili da haka, kuna buƙatar kula da zafin aiki na tacewa yayin aikin tacewa da

tabbatar dazazzabi na ruwa da matsa lamba.Lokacin tsaftace tacewa, kuna buƙatar bi

daidai hanyar wanke baya.

Yaya Sintered Metal Filters ke Aiki?

Kuna iya sauƙin fahimta lokacin da kuka duba abubuwan da ke biyo bayaJadawalin ƙa'idar aiki

Kamar yadda mai zuwa ne main8-Irina Theaiki manufa na karfe tacewa, da fatan zai taimaka muku

karin fahimtaga yaddaSintered karfe Tace zai iya taimakadon tace ruwa, gas da murya.

1.) Liquid & Gas Tace / Rabuwa

Sintered Metal tacewa na iya rage ko cire gaba ɗaya kwata-kwata daga iskar gas ko matsakaiciyar ruwa.

Musamman kwayoyin halitta na iyasun haɗa amma ba'a iyakance ga ɓangarorin da aka dakatar ba (launi, guntun ƙarfe, gishiri, da sauransu),

algae, kwayoyin cuta, fungi spores, da maras sosinadarai/ gurɓataccen halitta. Ƙarfe tace masu girma dabam

Za'a iya yin kewayon daga 0.2 µm - 250 µm.

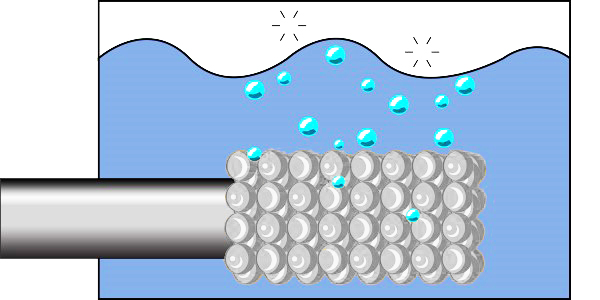

2.)Sparger

Wasu daga cikin aikace-aikacen Sparging:

Soda Carbonization

Gurasar Carbonization

OxygenCire Mai

Sparging shine shigar da iskar gas a cikin ruwa. Ana amfani da shi don ko dai cire iskar gas maras so

(tsirin iskar oxygen) koruwa mai narkewa. Hakanan ana iya amfani dashi don shigar da iskar gas a cikin ruwa (carbonization).

Sparging na gargajiya ya haifar da kumfatare da diamita na 6 mm. PM tace sparging yana ba da damar ƙarami

kumfa diamita, don haka kara da surface yankin nakumfa suna haifar da ingantaccen sparging

aikace-aikace ta rage lokaci tsari.

3.) Numfashin numfashi

Sintered karfe tace kuma ana amfani da matsayinnumfashin iskaa cikin cylinders, gearboxes, manifolds, na'ura mai aiki da karfin ruwa tsarin,

reservoirs, da sauran tsarin. Fitowar numfashi suna ba da damar daidaita matsi da iska/gas a ciki da waje na tsarin

yayin da yake toshe kwayoyin halitta daga shiga cikin tsarin. Fayafai masu tace tagulla da aka ƙera suna da tasiri musamman

a cikin injinan lantarki, hana shigowar ƙura, danshi, da sauran gurɓatattun abubuwa yayin da suke barin iska

musayar, wanda ke da mahimmanci don kiyaye yanayin cikin motar da kuma tabbatar da dacewarsa

aiki da tsawon rai. Za a iya wanke matatun ƙarfe a baya don cire abubuwan da ba su da yawa, suna ba su tsayi

tsawon rayuwa a matsayin hushin numfashi fiye da sauran kafofin watsa labarai masu tacewa.

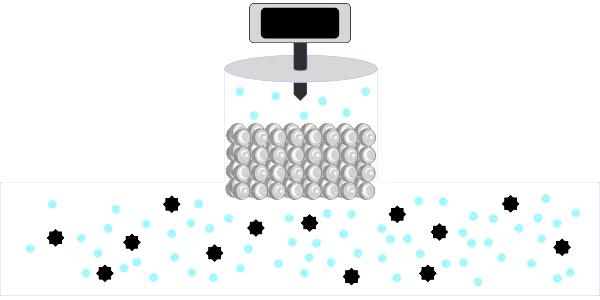

4.) Kariyar Sensor

Sintered Metal Filters kuma na iya kare kayan aikin lantarki azaman murfin, kamar ma'aunin zafi da sanyio,

daban-daban sensosi,keysassa na tsarin kiwon lafiya, da sauran samfurori masu mahimmanci daga ruwa,

ruwa, laka, kura, damatsin lamba.

5).

Na musammantacezai iya sarrafa kwararar ruwa a cikin iska, gas, vacuum, da tsarin kwarara ruwa. The

uniform din tacepore masu girma dabamba da izini ga daidaiton ƙa'idar kwarara mai maimaitawa da kare bawul, firikwensin,

da wani abu a kasaa cikin tsarin dagagurɓatattun abubuwa. Ana amfani da sarrafa kwarara cikin irin wannan

aikace-aikace kamar masu ƙidayar huhu, sarrafa iskar gasabubuwa, da jinkirta lokaciabubuwa a cikin

aikace-aikacen mota.

6.) Masu Silencers na iska

Hakanan za'a iya haɗa matattarar da aka haɗa da su ko kuma a haɗa su zuwa kowane dacewa da ake buƙata, yana ba su damar yin aiki azaman

shaye shiru.Tace ba zai iya kare solenoids kawai da manifolds daga gurɓatacce a cikin

tsarin amma kuma yana rage surutumatakin shaye-shaye daga tsarin. Theshiru shaye shayetacewa

kumarage iskan da ke fitowa daga tsarin, wandayana rage gurɓatar da ke tashi, Kariya

yanayi.

7.) Daidaita Guda / Matsa lamba

Matsalolin da aka ƙera na iya daidaitawa da sarrafa yawan kwararar tsarin da matsa lamba. Daidaitawa yana kare

tsarin adawa da karuwana ruwa kuma yana haifar da guda ɗaya kamar yadda iskar gas ko ruwa ke wucewa

da uniform pores.

Me ake Amfani da Filters na Sintered Don?

Don wannan tambayar, Haƙiƙa mutane da yawa za su yi tambaya Menene aikace-aikacen Filters ɗin ƙarfe na ƙarfe?

Bayan irin wannan tsari mai rikitarwa, inda za a yi sintirikarfe tace cartridgesa yi amfani?

Gaskiyar ita ce, zaku iya samun waɗannan matatun a masana'antu daban-daban.

Aikace-aikacen gama gari sun haɗa da waɗannan.

1) sarrafa sinadarai

Kuna iya nemo matatun ƙarfe da aka ƙera a cikin sinadarai masu ƙarfi da masana'antar sarrafa gas, gami da

masana'antar nukiliya.Lalacewar, yawan zafin jiki, da rashin mayar da martani ga sinadarai suna yin baƙin ƙarfe

tace wata fa'ida ce a ciki

masana'antar sarrafa sinadarai.

2) tace man fetur

Don tace man fetur, don tace mai daban-daban yadda ya kamata

Muna buƙatar amfani da matatun ƙarfe daban-daban bisa ga matakin digiri don kammala tacewa na

takamaiman man fetur dagakayan abinci.Ee, matatun ƙarfe da aka ƙera na iya taimaka muku cimma wannan burin.

Domin masu tace karfe ba sa amsawa da mai.

Saboda haka, ƙayyadaddun man fetur zai kasance ba tare da kowane gurɓataccen abu ba bayan tacewa.

Bugu da ƙari, za ku iya amfani da shi a yanayin zafi har zuwa 700 °, wanda ya zama ruwan dare a cikin tace man fetur.

3.) Samar da wutar lantarki

Ƙarfin wutar lantarki na ruwa yana buƙatar ci gaba da aiki na injin turbin. Duk da haka, da

muhalli awanda turbineyana aiki sau da yawa yana buƙatar tacewa don cimma jikin ruwa a ciki

wanda injin injin din ba shi da wani kazanta.

Idan injin turbin ya cika da ƙazanta, zai tashi sama kuma ya hana turbin daga juyawa.

sa'an nan kuma turbine zaiba samar da wutar lantarki ba. Kuna iya amfani da filtattun karfe don tabbatarwa

samar da wutar lantarki mai inganci da inganci.

Ana amfani da waɗannan filtattun don samar da wutar lantarki ta hanyar tace ruwa daga injin turbine.

Saboda ruwa ba ya lalata su, injin turbin zai yi aiki na dogon lokaci.

4.) samar da iskar gas

Wani muhimmin yanki na aikace-aikacen don matatun ƙarfe na sintered shine samar da iskar gas.

Fitar ƙarfe da aka ƙera suna da amfani sosai a samar da iskar gas saboda ba sa amsawa da iskar gas,

kuma za ku iya amfani da sua wurare daban-daban.

5.) Abinci da abin sha

Masu tace ƙarfe suna fitar da muhimman abubuwan gina jiki da ruwan 'ya'yan itace a masana'antar sarrafa abinci da abin sha.

Masu tace ƙarfe suna tacewa sosai kuma suna hana waɗannan sinadarai daga wankewa yayin sarrafa su.

Amfanin matatun ƙarfe iri ɗaya shine ba sa amsa da takamaiman abinci ko abubuwan sha.

Lokacin amfani da waɗannan masu tacewa yana ba da garantin ingancin aikin samar da ku.

9. Wane irinSintered Karfe TaceHENGKO zai iya bayarwa?

HENGKO main wadata 316L, 316 da tagulla sintered karfe filers. babban siffa kamar jeri mai zuwa:

1.Tace Bakin KarfeDisc,

2.BakinTace KarfeTube,

3.Bakin Tace KarfePlate,

4.Tace Bakin KarfeKofuna,

da sauransu, kowane nau'i na aikin ku yana buƙata.

Tabbas, muna samarwaSabis na OEM

1.OEMSiffar:Disc, Kofin,Tube, Plate ect

2.KeɓanceGirman, Tsawo, Fadi, OD, ID

3.Girman Pore na Musamman /Budewadaga 0.1 μm - 120 μm

4.Keɓance Kauri daban-daban

5. Mono-Layer, Multi-Layer, Mixed Materials

6.Haɗin ƙirar ƙira tare da gidaje 304 bakin karfe

Don ƙarin bayanan OEM ɗin ku, tuntuɓi HENGKO A Yau!

Har yanzu kuna da Tambayoyi Kamar Sanin ƙarin Cikakkun bayanai Don Sensor Kula da Humidity,

Da fatan za a ji 'Yanci Don Tuntuɓar Mu Yanzu.

Hakanan zaka iyaAiko mana da ImelKai tsaye Kamar Haka:ka@hengko.com

Zamu Aika Baya Tare da Sa'o'i 24, Godiya ga Majinjin ku!

Aiko mana da sakon ku:

Lokacin aikawa: Agusta-20-2022