Menene Sintering?

Mai Sauƙi don Cewa, Sintering shine tsarin kula da zafi da ake amfani da shi don canza kayan foda zuwa babban taro, ba tare da kai ga cikakken narkewa ba.

Wannan sauyi yana faruwa ta hanyar dumama kayan da ke ƙasa da inda yake narkewa har sai barbashinsa suna manne da juna.Ana amfani da Sintering sosai a masana'antu daban-daban kamar ƙarfe, yumbu, har ma da bugu na 3D don samar da abubuwa masu ƙarfi da ƙarfi daga foda.

Amma ka san cewa manufar sintering ba sabon zamani ba ne?

A haƙiƙa, ana iya gano asalinsa a kusan 3000 BC, lokacin da aka yi amfani da shi don yin abubuwan yumbu.Fahimtar kimiyya ta zamani da kuma yaɗuwar amfani da masana'antu na sintering, duk da haka, sun haɓaka musamman a cikin ƙarnin da ya gabata.

Kamar yadda zaku iya tunanin, sintering yana taka muhimmiyar rawa a cikin tarin aikace-aikace.Daga yin walƙiya, yumbu capacitors, da rawanin hakori zuwa gina manyan kayan aikin masana'antu, sintering ya tabbatar da zama makawa.

Daban-daban na Sintering

Yanzu da kuka san menene sintering da kuma yadda ake amfani da shi a cikin tarihi, lokaci yayi da zaku gabatar muku da nau'ikan sintering daban-daban.Ee, akwai fiye da hanya ɗaya don sinter!

Farko samashi ne m-state sintering.Wannan nau'in shine mafi asali kuma na kowa nau'i na sintering.Anan, kayan foda suna zafi har sai barbashi sun fara haɗuwa tare.Yana kama da yadda za ku gina ginin yashi - hatsin yashi yana tare, amma ba sa narke.

Na gaba,muna da ruwa lokaci sintering.Wannan nau'in ya ƙunshi cakuda kayan biyu ko fiye.Ana ɗora cakuda zuwa wani wuri inda ɗayan kayan ya narke kuma ya samar da wani lokaci na ruwa, wanda ke taimakawa wajen haɗa sauran ƙwayoyin da suka rage tare.

Na ukua cikin jerin an kunna sintering.A wannan yanayin, ana amfani da ƙari ko mai kara kuzari don hanzarta aikin sintiri.Yi la'akari da shi azaman ƙara yisti zuwa kullu - yana sa gurasar ta tashi da sauri.

Daga karshe,akwai dabarun sintering na taimakon matsin lamba kamar matsi mai zafi da walƙiya na plasma sintering.Kamar yadda sunan ya nuna, waɗannan fasahohin suna amfani da matsa lamba a hade tare da zafi don hanzarta aikin sintiri da samar da abubuwa masu yawa.

Kowane nau'in sintering yana da nasa fa'idodi kuma ana amfani dashi don takamaiman aikace-aikace.Zaɓin ya dogara da dalilai irin su kayan da ake amfani da su, abubuwan da ake so na samfurin ƙarshe, da kayan aiki da ke samuwa.A cikin ɓangarorin masu zuwa, za mu zurfafa zurfafa cikin takamaiman kayan da aka ƙera da kuma tsarin sintiri da kansa.

Kasance cikin sauraron don ƙarin haske mai ban sha'awa game da duniyar sintering!

Bincika Abubuwan Sintered

Sa'an nan gaba muna buƙatar fahimtar nau'o'in kayan da aka yi amfani da su.

Na tabbata ya zuwa yanzu, kuna samun rataye na tsarin sintering.Amma menene game da samfuran wannan tsari mai ban sha'awa?

Ɗaya daga cikin abubuwan da aka fi samarwa shine ƙarfe da aka ƙera.Tsarin ya ƙunshi haɗawa da ƙirƙirar foda na ƙarfe a ƙarƙashin zafi, juya shi zuwa ƙarfe mai ƙarfi.Sakamakon shine karfe tare da babban matakin tsabta da daidaituwa.Ana iya samun ƙarfen da aka ƙera a masana'antu daban-daban, tun daga kayan aikin mota zuwa na'urar da aka sanya a cikin likitanci, saboda ƙarfinsa da haɓakarsa.

Na gaba,bari mu yi magana game da sintered dutse.Ana samar da dutsen da aka ƙera ta hanyar yin amfani da zafi da matsa lamba ga ma'adanai na halitta, yumbu, da feldspar, samar da wani abu da ba zai iya lalacewa ba.Sau da yawa za ku sami jigon dutse a cikin manyan wuraren zirga-zirga kamar wuraren dafa abinci ko fale-falen gidan wanka, inda karko yana da mahimmanci.

Sintering kuma yana taka muhimmiyar rawa a cikin yumbu.Tsarin yana ba mu damar ƙera yumbura zuwa nau'i-nau'i masu yawa tare da rikitattun geometries waɗanda ba za su yiwu ta hanyar gargajiya ba.Daga fale-falen yumbura zuwa tukwane, sintiri ya yi tasiri mai tasiri akan wannan fannin.

Daga karshe,akwai wasu daban-daban na musamman sintered kayan bincike.Waɗannan kewayo daga kayan haɗaɗɗun abubuwa, kamar abubuwan haɗin ƙarfe- yumbura, zuwa kayan aiki masu ƙima, inda abun da ke ciki ya bambanta a cikin ɓangaren.

An Bayyana Tsarin Tsara Tsara

Bari mu ci gaba daga samfurori zuwa tsarin kanta.Ta yaya sintering ke faruwa, kuma menene mahimmin matakan da aka haɗa?

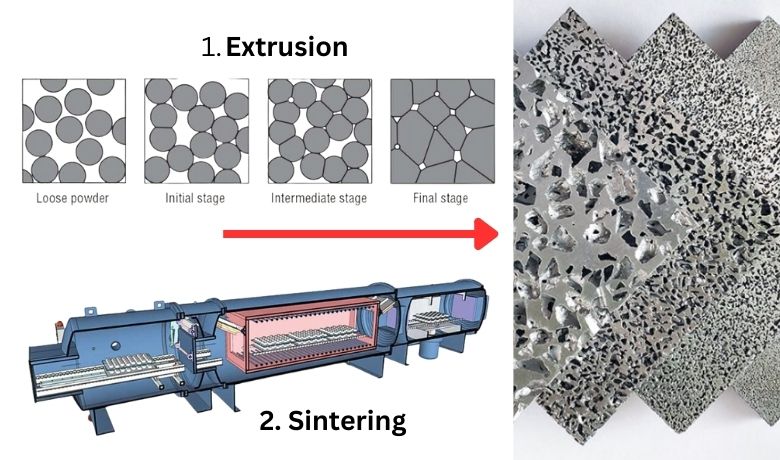

Don farawa da, matakan da aka riga aka tsara suna da mahimmanci.Danyen kayan, ko ƙarfe ne, yumbu, ko akasin haka, dole ne a shirya su cikin foda.Sannan ana siffanta wannan foda zuwa yadda ake so, sau da yawa ta hanyar da ake kira 'green compacting'.

Na gaba ya zo zuciyar aikin: tsarin sintiri.Ana dumama foda mai siffa a cikin yanayi mai sarrafawa, yawanci tanderu, zuwa zafin jiki kusa da wurin narkewa.Wannan yana ba da damar barbashi don haɗawa tare ba tare da cikakken narkewa ba, samar da ƙaƙƙarfan taro.

Da zarar aikin sintiri ya cika, kayan ya shiga cikin yanayin sanyaya.Ana buƙatar sarrafa wannan a hankali, saboda saurin sanyaya zai iya haifar da tsagewa ko wasu al'amura na tsari.Sanyaya a hankali yana ba da damar kayan don daidaitawa da ƙarfafa yadda ya kamata.

Daga karshe,ba za mu iya mantawa da abubuwan da ke tasiri sintering, musamman, zazzabi da lokaci.Matsakaicin zafin jiki yana buƙatar zama babba don sauƙaƙe haɗin gwiwa amma ƙarancin isa don hana cikakken narkewa.Hakazalika, lokacin da kayan ke ciyarwa a cikin tsarin sikelin na iya tasiri sosai ga kayan samfurin ƙarshe.

A cikin sashe na gaba na saga na mu na singtering, za mu nutse cikin zurfin tacewa tare da buɗe sharuɗɗan da ake buƙata don sintering.Don haka ku kasance tare!

Filters Sintered: Hasken Aikace-aikacen

Mun riga mun rufe ainihin abubuwan da ake amfani da su na sintering, mun bincika nau'ikan kayan da ba a taɓa gani ba, kuma mun tattauna dalla-dalla dalla-dalla.

Yanzu, bari mu mai da hankali kan atakamaiman aikace-aikace na sintering tacewa.

Wataƙila ɗaya daga cikin aikace-aikacen da aka fi sani na sintiri shine a cikin ƙirƙirar matatun ƙarfe na sintered.Ana samar da waɗannan matatun ne daga foda na ƙarfe, an haɗa su kuma an haɗa su don ƙirƙirar matsakaici mai ƙarfi amma mai ƙarfi.Girman ramin waɗannan matatun za a iya sarrafa shi daidai, yana samar da ingantattun damar tacewa idan aka kwatanta da matatun ragar waya na gargajiya.

Kuna iya mamaki,me yasa amfanisintered karfe tace?Amsar ta ta'allaka ne ga dorewarsu da juriya ga yanayin zafi da matsi.Waɗannan kaddarorin suna sa matatun ƙarfe da ba su da mahimmanci a cikin masana'antun da suka kama daga magunguna zuwa sinadarai da samar da abinci da abin sha.

Wani aikace-aikacen ban sha'awa mai ban sha'awa na sintering a cikin tacewa shine tace gilashin sintered.Ana yin waɗannan ta hanyar haɗa ƙananan ɓangarorin gilashi tare a babban yanayin zafi.Ana amfani da su sau da yawa a dakunan gwaje-gwaje don tacewa da rarraba iskar gas saboda tsananin juriyarsu da madaidaicin girman rami.

Abubuwan tacewa, ƙarfe ne ko gilashi, suna misalta iyawar sintirin ƙirƙira mafi girman kayan tare da fa'idodi daban-daban.

Fahimtar Yanayin Sintering

Yanzu, bari mu mai da hankalinmu ga sharuɗɗan ɓacin rai.Lokacin da muke magana game da tsari na sintering, yanayin da yake faruwa a ƙarƙashinsa yana da matukar muhimmanci.

Na farko,yanayin zafin jiki yana taka muhimmiyar rawa a cikin tsari.Yana buƙatar zama kawai a ƙasa da wurin narkewa na kayan, don ba da damar barbashi su haɗa ba tare da cikakken narkewa ba.Daidaitaccen ma'auni ne wanda zai iya tasiri sosai ga ingancin samfurin ƙarshe.

Sannanakwai batun iskar gas.Kuna iya yin mamaki, "Wane gas ne ake amfani da shi wajen sintiri?"Yawanci, ana aiwatar da sintering a cikin yanayi mai sarrafawa don hana halayen da ba a so a tsakanin kayan da gas ɗin da ke kewaye.Sau da yawa, ana amfani da iskar gas kamar nitrogen ko argon, kodayake zaɓi na musamman ya dogara da kayan da aka lalata.

Har ila yau, matsin lamba yana shiga cikin wasa, musamman ma a cikin dabarun ƙwaƙƙwaran matsa lamba.Matsakaicin matsa lamba zai iya haifar da abubuwa masu yawa, kamar yadda ake tilasta barbashi kusa da juna.

Daga karshe,kayan kayan aiki da kayan aikin da aka yi amfani da su sune mahimman abubuwa.Kayayyaki daban-daban suna amsa daban-daban don zafi da matsa lamba, suna buƙatar yanayi daban-daban don ingantacciyar sintesa.Nau'in tanderu ko na'ura na iya yin tasiri a kan tsarin, kamar yadda za mu tattauna a sashe na gaba.

Kasance cikin saurare yayin da muke ƙarin bincike game da injunan ƙwanƙwasa da rawar da suke takawa a cikin tsarin sintering!

Kayan Aikin Ginawa: Kallon Injin Sintering

Har ya zuwa yanzu, muna da cikakken bincike game da manufar sintering, sintered kayan, da kuma tsarin kanta.

Yanzu bari mu haskaka babban ɗan wasa a bayan fage:na'urar sintiri.

Na'ura mai ƙwanƙwasa ita ce ginshiƙan ginshiƙan tsari.Amma menene ainihin na'urar sintiri?Mahimmanci, tanderu ce ta musamman da aka ƙera don aiwatar da aikin sintiri a ƙarƙashin yanayin kulawa da kyau.

Akwaidaban-daban na sintering injisamuwa, kowane dace da daban-daban kayan da sintering hanyoyin.

1. Waɗannan sun haɗa daCigaban injunan sintering(amfani da shi a cikin masana'antun da ke buƙatar samar da girma mai girma),

2.Batch sintering inji(mafi kowa a cikin labs ko don samar da ƙananan ƙaranci), da

3. Vacuum sintering inji(wanda ke ba da damar sintiri a cikin sarari ko yanayi mai sarrafawa).

Yadda injin sintiri ke aiki yana da sauƙi amma mai ban sha'awa.Yana dumama kayan foda iri ɗaya zuwa takamaiman zafin jiki, yana kiyaye wannan zafin na wani ƙayyadadden lokaci, sannan yana sanyaya kayan a hankali, duk yayin da yake tabbatar da yanayin da ke ciki ana sarrafa shi.

Zaɓin na'ura mai dacewa daidai yana da mahimmanci kuma ya dogara da dalilai da yawa, ciki har da kayan da za a yi amfani da su, abubuwan da ake so, da takamaiman yanayin da ake bukata.

Muhimmanci da Makomar Sintering

Yanzu ya yi da za a yi tunani a kan babban hoto:Abin da ake amfani da sintering, kumame yasa yake da mahimmanci?

Theaikace-aikacena sintering suna da yawa kuma iri-iri.Ana amfani da shi don ƙirƙirar samfura masu ɗorewa, masu ɗorewa tare da hadaddun geometries, daga abubuwan masana'antu zuwa kayan masarufi.Sintering yana ba mu damar samar da kayan aiki masu inganci, kamar ƙarfe na ƙarfe da masu tacewa, tare da ƙayyadaddun kaddarorin kamar girman pore da aka sarrafa da ingantaccen ƙarfi.

Ammamenene makomar sintering yayi kama?Abubuwan da ke tasowa suna nuna haɓakar amfani da dabarun sintiri na taimakon matsin lamba don samar da kayan haɓaka.Haɓaka ingantattun injunan sintering da kuma amfani da sintering a masana'anta ƙari (bugu 3D) wasu abubuwa ne masu ban sha'awa.

Duk da waɗannan ci gaban, sintering kuma yana fuskantar ƙalubale, kamar samun babban iko kan tsarin da rage yawan amfani da makamashi.Magance waɗannan zai zama maɓalli don buɗe cikakkiyar damar yin ɓarna a nan gaba.

Ƙarshe:Sintering, yayin da tsari mai rikitarwa, yana da tasiri mai mahimmanci akan masana'antu daban-daban.Ƙarfinsa don canza foda mai sauƙi zuwa ƙaƙƙarfan abubuwa masu ƙarfi, hadaddun kayan aiki ya sa ya zama tsari mai mahimmanci.Yayin da muke sa ran nan gaba, juyin halitta da gyare-gyare na sintirin yin alƙawarin damammaki masu ban sha'awa don sabbin kayayyaki da aikace-aikace.

FAQ

1. Menene tsarin sintering?

Sintering shine tsarin kula da zafi wanda ke canza kayan foda zuwa babban taro ba tare da narke kayan gaba daya ba.Ya haɗa da dumama kayan foda a ƙasan inda yake narkewa har sai ɓangarorin sun fara manne da juna, suna yin taro mai ƙarfi.Ana amfani da wannan tsari a masana'antu daban-daban kamar ƙarfe, yumbu, masana'anta da ƙari don samar da abubuwa masu yawa da ƙarfi daga foda.

2. Ta yaya sintering ke aiki?

Tsarin sintiri ya ƙunshi manyan matakai guda uku: dumama, riƙewa, da sanyaya.An fara haɗa kayan foda kuma an kafa su zuwa siffar da ake so, sa'an nan kuma zazzage su a cikin yanayi mai sarrafawa zuwa yanayin zafi kusa da inda yake narkewa.Zafin yana haifar da barbashi don haɗawa tare, suna samar da ƙaƙƙarfan taro.Bayan kiyaye wannan zafin jiki na wani ƙayyadadden lokaci, kayan ana sanyaya su a hankali don hana fasa ko wasu batutuwan tsarin.

3. Waɗanne kayan za a iya haɗa su?

Ana iya haɗa abubuwa da yawa, gami da ƙarfe, yumbu, robobi, da gilashi.Kayayyakin daban-daban suna buƙatar yanayi daban-daban, kamar zafin jiki, matsa lamba, da yanayi.Wasu kayan ana iya haɗa su kai tsaye, yayin da wasu suna buƙatar ƙari ko ɗaure don sauƙaƙe aikin.

4. Menene matattara da aka lalata, kuma me ya sa ake amfani da shi?

Fitar da aka yi da ita wani nau'in tacewa ne da ake samarwa ta hanyar sarrafa ta.Ana iya yin shi daga karfe, yumbu, ko foda na gilashi, a haɗa shi da zafi har sai ɓangarorin suna haɗuwa tare.Girman pore na waɗannan filtattun za a iya sarrafa shi daidai, yana samar da ingantattun damar tacewa idan aka kwatanta da matatun gargajiya.Fitar da keɓaɓɓu suna da tsayi sosai kuma suna jure yanayin zafi da matsi, yana mai da su amfani a masana'antu daban-daban kamar magunguna, sinadarai, da samar da abinci da abin sha.

5. Ta yaya ake amfani da sintering a masana'anta ƙari (bugu 3D)?

A ƙari masana'anta, ko 3D bugu, sintering ana amfani da su a hanyoyi kamar zažužžukan Laser sintering (SLS) da kai tsaye karfe Laser sintering (DMLS).Waɗannan hanyoyin sun haɗa da yin amfani da Laser don karkatar da kayan foda ta Layer, gina abin da ake so na 3D.Ikon sarrafa tsarin sintiri daidai yana ba da damar samar da sifofi masu rikitarwa da geometries waɗanda zasu yi wahala ko ba za a iya cimma su tare da hanyoyin masana'anta na gargajiya ba.

6. Menene makomar sintering?

Makomar sintering tana da kyau, tare da ci gaba a cikin fasahar buɗe sabbin damar.Misali, dabarun sintering na taimakon matsin lamba suna ƙara shahara don samar da kayan haɓaka.Ƙirƙirar ingantattun ingantattun injunan sintering, da kuma amfani da ƙwanƙwasa a masana'anta, wasu abubuwa ne masu ban sha'awa.Koyaya, ƙalubalen kamar samun babban iko akan tsari da rage yawan amfani da makamashi suna buƙatar magancewa don buɗe cikakkiyar damar yin amfani da su.

Ko kuna neman aiwatar da ayyukan sintering a cikin ayyukanku ko neman ingantattun kayan sintered don ayyukanku, HENGKO yana nan don taimakawa.Ƙwararrun ƙwararrun mu a shirye suke don ba da shawara, mafita, da ayyuka waɗanda suka dace da buƙatunku na musamman.

Kada ku yi jinkirin tuntuɓar mu don ƙarin haske game da tsari mai ban sha'awa na sintering ko don bincika samfuran samfuranmu da sabis masu yawa.Kawai sauke mana imel aka@hengko.com, kuma za mu tuntube mu da sannu.mun himmatu don taimaka muku juya yuwuwar powdered zuwa ingantaccen nasara!

Aiko mana da sakon ku:

Lokacin aikawa: Jul-03-2023