Sintering yana taka muhimmiyar rawa a masana'antar masana'antu, yana ba da damar samar da ingantattun abubuwa masu ɗorewa.Fahimtar ginshiƙai na sintering yana da mahimmanci ga injiniyoyi, masu bincike, da masu sha'awa iri ɗaya.Wannan labarin yana da niyya don zurfafa cikin ra'ayin sintering, bincika tsarinsa, tattauna aikace-aikacensa, da nuna fa'idodi da iyakokinsa.

Menene Sintering?

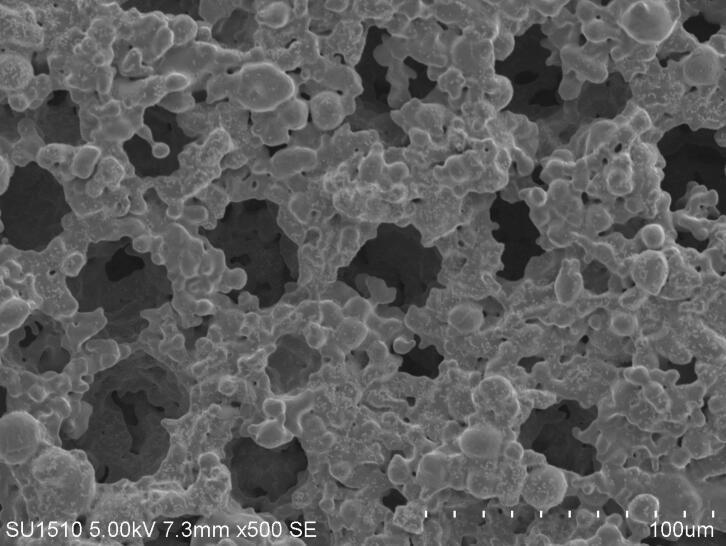

Sintering wani tsari ne wanda ya ƙunshi ƙaddamar da kayan foda zuwa cikin ƙaƙƙarfan taro ta amfani da zafi.Ba kamar tsarin narkewa na gargajiya ba, sintering ba ya kaiwa wurin narkewar kayan.Madadin haka, yana amfani da yaduwar atom a cikin ɓangarorin, wanda ke haifar da haɗin gwiwa da haɓakawa.Wannan tsari yana haifar da ingantaccen tsari tare da ingantattun kayan aikin injiniya.

Sintering kuma yana da fadi da kunkuntar hankali.Don ma'ana mai faɗi, sintering wani tsari ne wanda sako-sako da foda ke haɗawa cikin tubalan ta wani ƙarfi mai ƙarfi a wani zafin jiki.Amma sintering a fagen yin ƙarfe tsari ne da ke haɗa foda ta ƙarfe da sauran kayan da ke ɗauke da ƙarfe cikin kyakkyawan aikin ƙarfe na wucin gadi ta hanyar haɗakarwa, samar da shi yana da ƙarfi.Sun ƙunshi matakai daban-daban na physicochemical Ko da yake dukansu sun yi amfani da kalmar sintering.

Tsarin Sintering

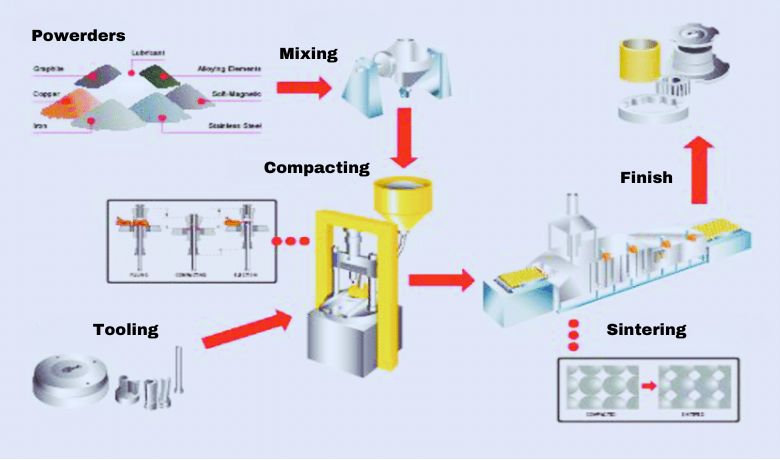

Tsarin sintiri ya ƙunshi matakai da yawa.Da farko, an samar da albarkatun ƙasa zuwa wani takamaiman tsari, yawanci a cikin nau'in foda.Wannan foda an haɗa shi ta amfani da matsa lamba don tabbatar da daidaito da kuma kawar da ɓoyayyen.Bayan haka, an ƙaddamar da kayan da aka haɗa zuwa dumama mai sarrafawa a cikin tanderun da aka yi amfani da su.Ana sarrafa zafin jiki a hankali don sauƙaƙe haɗin ɓangarorin ba tare da haifar da cikakken narkewa ba.A lokacin dumama, barbashi suna yin yaduwa, wanda ke haifar da samuwar wuyan wuyansa da ƙima.Mataki na ƙarshe ya haɗa da sanyaya samfurin da aka ƙera, yana ba shi damar ƙarfafawa cikin tsari mai tsauri da haɗin kai.

Foda da muka saba cewa ita ce foda ta karfe ko kuma taurin foda.Sana'a tsari ne na samun kayan ko samfur a cikin ƙarfin da ake buƙata da kuma abubuwan da ake buƙata saboda haɗin jiki da sinadarai tsakanin barbashi a yanayin zafi ƙasa da wurin narkewa na babban ɓangaren.HENGKO yana da jerin samfuran sintirin foda na nau'ikan ƙayyadaddun bayanai da girma dabam ciki har dadiski tace, kofin tace,tace kyandir,takardar taceda sauransu.Our sintering bakin karfe samfurin yana da amfani da babban ƙarfi, Good permeability, Madaidaicin tacewa daidaito da lalata juriya, dace da yawa yankunan.Hakanan ana bada sabis na musamman kamar yadda kuka nema.

Kowane mataki a cikin tsarin sintering yana hulɗa da juna, kuma mayar da hankali mataki ne mai mahimmanci a cikin tsarin sintering, don haka menene ma'anar tattarawa? bukatu na ƙarfafa fashewa tanderu kafin danye da man fetur shigar da fashewa tanderu.Ana iya samun manyan alamomin fasaha da tattalin arziki da fa'idodin tattalin arziki bayan an yi amfani da concentrateis a cikin fashewar tanderu.Abin da ake kira "yi mafi kyawun amfani da komai" da yin amfani da kayan aiki mafi kyau.Hakanan wani nau'in wayar da kan jama'a ne na ceto da kare muhalli.

Abubuwan Da Suka Shafi Sintering

Dalilai da yawa suna yin tasiri akan tsarin sintiri, gami da zafin jiki, ƙimar dumama, matsa lamba, girman barbashi, da abun da ke ciki.Zazzabi yana taka muhimmiyar rawa wajen tantance motsin motsin rai da sakamakon kayan abu.A dumama kudi rinjayar da densification tsari, kamar yadda m dumama iya haifar da m barbashi bonding.Ana amfani da matsi yayin daɗaɗɗa don haɓaka gyare-gyaren barbashi da kawar da porosity.Girman barbashi da abun da ke ciki suna tasiri da halayen sintirin, tare da ƙananan barbashi da abubuwan haɗin kai masu kama da haɓaka mafi kyawun ƙima.

Daga zahirin ma’anar kalmar sintering, kalmar kona ita ce amfani da wuta, dole ne a sami harshen wuta tare da zafi mai zafi.Kuma dole ne a yi aikin sintiri a cikin yanayin zafi mai yawa.Ana yin babban zafin jiki ta hanyar ƙona man fetur.Matsakaicin zafin jiki, saurin ƙonawa, nisa na bandungiyar ƙonawa, yanayi a cikin kayan da aka ƙera, da dai sauransu zai shafi ci gaban tsarin haɓakawa da ingancin samfuran ƙarshe.Kuma waɗancan abubuwan suna da alaƙa da sifofin zahiri da sinadarai na man fetur da sashi.Sabili da haka, abubuwan da ke cikin jiki da sinadarai na man fetur wani muhimmin abu ne wanda ke shafar tsarin sikelin.

Metaphor wani abu ba zai iya zama ba tare da tushen abin da suke rayuwa ba.Man fetur da albarkatun kasa suna kama da fata kuma itacen da ke da dangantaka ba makawa.Ba tare da ko ɗaya ba, Tsarin sintering ba zai iya faruwa ba.Amma Sintered man galibi yana nufin ƙaƙƙarfan mai da ke ƙonewa a cikin kayan.Mafi yawan amfani da ita shine foda coke da anthracite, da dai sauransu. Sintered albarkatun kasa, yafi suna da baƙin ƙarfe tama, da manganese tama, da sauran ƙarfi, man fetur da kuma masana'antu sharar gida.

Daban-daban na Sintering

Sintering ya ƙunshi dabaru daban-daban waɗanda aka rarraba bisa ga hanyoyin da yanayin da ke cikin tsari.Fahimtar nau'ikan sintering daban-daban yana da mahimmanci don zaɓar hanyar da ta dace don takamaiman aikace-aikace.Ga wasu nau'ikan sintering gama gari:

1 Ƙarfafa-Jihar Sintering

Ƙaƙƙarfan yanayi, wanda kuma aka sani da yaduwa bonding, hanya ce da ake amfani da ita sosai.A cikin wannan tsari, kayan foda suna fuskantar yanayin zafi a ƙasa da wuraren narkewa.Yayin da yawan zafin jiki ya karu, yaduwar atomic yana faruwa a tsakanin ɓangarorin da ke kusa da su, yana sauƙaƙe samuwar wuyan wuyansa da haɗin kai.Kawar da voids da sake shirya barbashi kai ga densification da samuwar m taro.

Ana amfani da tsattsauran ra'ayi a cikin samar da yumbu, irin su alumina da alumina, da kuma ƙera foda na ƙarfe.An fi so a lokacin da ake adana abubuwan sinadaran da tsabtar kayan yana da mahimmanci.Ta hanyar a hankali sarrafa ma'auni, kamar zafin jiki, lokaci, da matsa lamba, ana iya samun abubuwan da ake so.

2 Liquid-Phase Sintering

Sintering-lokacin ruwa ya ƙunshi ƙari na wani lokaci na ruwa don taimakawa cikin daidaitawar barbashi da haɗin kai yayin aiwatar da sintering.Lokaci na ruwa, sau da yawa wani abu mai ƙarancin narkewa, yana aiki azaman mai ɗaure ko juyi, yana rage yawan zafin jiki da ake buƙata don ƙima.Wannan hanya tana da amfani musamman a lokacin da ake ɓata kayan da ke da manyan wuraren narkewa ko lokacin haɓaka ƙimar ƙima.

Yayin sintering na lokaci-ruwa, lokaci na ruwa yana yaduwa tsakanin barbashi, yana haɓaka gyare-gyaren barbashi da haɓaka samuwar wuyansa da ƙima.Kasancewar lokaci na ruwa kuma yana ba da damar kawar da ƙazanta kuma yana sauƙaƙe ƙaddamar da kayan aiki tare da hadaddun abubuwa.

Ana amfani da sintering na lokaci-lokaci a cikin samar da siminti na siminti, inda aka haɗa barbashi na carbide tungsten ta amfani da abin ɗaure mai tushen cobalt.Ana kuma amfani da ita wajen ƙera wasu yumbu da ƙarfe na ƙarfe, kamar bakin karfe.

3 Kunna Sintering

Kunna sintering, wanda kuma aka sani da filin-taimaka sintering ko spark plasma sintering, wata sabuwar dabara ce ta sintering wadda ke amfani da waje makamashi kafofin don inganta da yawa.Ya ƙunshi aikace-aikacen filin lantarki, wutar lantarki, ko radiyo na lantarki don haɓaka aikin sintiri.

Tushen makamashi na waje yana haɓaka yaduwar atomic, yana haifar da saurin wuyan wuyansa da ƙima.Aiwatar da makamashin lantarki yana haifar da dumama gida, yana rage lokacin ɓacin rai kuma yana ba da damar ƙaddamar da kayan a ƙananan yanayin zafi.Wannan dabarar tana ba da fa'idodi irin su haɓaka haɓakar haɓaka, rage haɓakar hatsi, da ingantaccen iko akan microstructure da kaddarorin.

Kunna sintering yana samun aikace-aikace a fagage daban-daban, gami da samar da ci-gaba na yumbu, kayan aiki, da abubuwan haɗaka.Yana da fa'ida musamman ga kayan da ke da manyan wuraren narkewa, hadaddun abubuwan da ke tattare da su, ko iyakancewar rashin daidaituwa.

4 Sauran Nau'o'in Sintering

Baya ga nau'ikan da aka ambata a baya, akwai wasu ƙwararrun hanyoyin sintering da yawa waɗanda aka keɓance da takamaiman aikace-aikace.Waɗannan sun haɗa da injin injin microwave, inda ake amfani da makamashin microwave don dumama da sarrafa kayan, da matsi-taimaka matsi, wanda ya haɗu da matsa lamba da zafi don haɓaka ƙima.

Bugu da ƙari, zaɓaɓɓen Laser sintering (SLS) da electron biam sintering (EBS) ƙarin fasaha ne na masana'anta waɗanda ke amfani da katako mai ƙarfi don zaɓar kayan foda, Layer Layer, don samar da hadaddun abubuwa masu girma uku.

Kowane nau'in sintering yana ba da fa'idodi na musamman kuma an zaɓa bisa ga kaddarorin kayan, sakamakon da ake so, da takamaiman aikace-aikace.

Aikace-aikace na Sintering

Sintering yana samun aikace-aikace masu yawa a cikin masana'antu daban-daban saboda ikonsa na canza kayan foda zuwa sassa masu ƙarfi tare da ingantattun kaddarorin.Bari mu bincika wasu mahimman wuraren da ake amfani da sintering sosai:

1 - Ceramics

Ceramics ɗaya ne daga cikin filayen farko waɗanda ake amfani da sintering sosai.Sintered tukwane suna nuna ingantacciyar ƙarfin inji, taurin, da kwanciyar hankali.Ana amfani da Sintering wajen kera fale-falen yumbura, kayan sanitaryware, kayan aikin yankan, kayan da aka cire, da insulators na lantarki.Ta hanyar sarrafa ma'auni a hankali, kayan yumbu na iya cimma ƙimar da ake so, porosity, da microstructure don takamaiman aikace-aikace.

2 - Karfe

A aikace-aikacen ƙarfe, ana amfani da sintering don kera nau'ikan abubuwan ƙarfe da yawa.Wannan ya haɗa da gears, bearings, bushings, ɓangarorin mota, da kayan aikin tsari.Ƙarfe, irin su baƙin ƙarfe, aluminum, da bakin karfe, an haɗa su kuma an haɗa su don samar da sassa masu ƙarfi tare da kyawawan kayan inji.Abubuwan da aka haɗa da ƙarfe galibi suna nuna ƙarfi mafi girma, juriya, da daidaiton girma idan aka kwatanta da sassan simintin gargajiya.

3 - Haɗin kai

Sintering yana taka muhimmiyar rawa wajen samar da kayan da aka haɗa, inda aka haɗa nau'i biyu ko fiye don ƙirƙirar kayan aiki tare da kayan haɓaka.A cikin kera abubuwan haɗin ƙarfe na matrix (MMCs) da yumbu matrix composites (CMCs), ana amfani da sintering don haɗa kayan ƙarfafawa, kamar fibers ko barbashi, tare da kayan matrix.Wannan yana haɓaka ƙarfi, taurin kai, da ƙaƙƙarfan abin haɗaɗɗiyar da aka samu.

4 - Powder Metallurgy

Ƙarfe na foda, reshe na musamman na ƙarfe, ya dogara sosai akan sintiri.Ya ƙunshi samar da abubuwan ƙarfe daga foda na ƙarfe.Ta hanyar matakai kamar haɗakarwa da ƙwanƙwasa, za a iya kera ɓangarorin sassa masu sarƙaƙƙiya tare da sifofi masu rikitarwa.Ana amfani da ƙarfe na foda da yawa a cikin masana'antar kera don samar da kayan aiki, camshafts, da kujerun bawul, haka kuma a cikin kera kayan aikin yankan da masu tacewa.

5 - 3D Bugawa / Ƙirƙirar Ƙira

Sintering yana taka muhimmiyar rawa a cikin fasahohin masana'antu kamar zaɓin Laser sintering (SLS) da kuma igiyar lantarki (EBS).A cikin waɗannan matakai, kayan foda suna zaɓin sintered Layer ta Layer, bisa ƙira na dijital, don ƙirƙirar abubuwa masu girma dabam uku.Sintering yana ba da damar ƙarfafawa da haɗin kai na kayan foda, wanda ya haifar da cikakkun sassa masu yawa da aiki.Ana amfani da wannan fasaha a masana'antu daban-daban, ciki har da sararin samaniya, kiwon lafiya, da samfuri.

6 Injiniyan Lantarki da Lantarki

Ana amfani da Sintering wajen samar da kayan lantarki da na lantarki.A cikin kera yumbu na lantarki, irin su capacitors, varistors, da thermistors, ana amfani da sintering don haɗa ɓangarorin yumbu, ƙirƙirar abubuwa masu yawa da lantarki.Hakanan ana amfani da sintering wajen ƙirƙira lambobin sadarwa na lantarki, marufi na semiconductor, da abubuwan haɗin allon kewayawa.

Waɗannan su ne kaɗan kaɗan na aikace-aikace iri-iri na sintering.Ana ci gaba da yin bincike da kuma tsaftace tsarin don saduwa da buƙatun ci gaba na masana'antu daban-daban, yana ba da damar samar da kayan aiki da kayan aiki masu mahimmanci.

Amfanin Sintering

Sintering yana ba da fa'idodi da yawa waɗanda suka sa ya zama hanyar masana'anta da aka fi so a masana'antu daban-daban.Bari mu bincika wasu mahimman fa'idodin:

1 Rukunin Siffai da Tsare-tsare

Ɗaya daga cikin mahimman fa'idodin sintering shine ikonsa na samar da abubuwan haɗin gwiwa tare da sifofi masu rikitarwa da ƙira.Ta hanyar amfani da kayan foda, sintering yana ba da damar samar da sassa tare da rikitattun geometries waɗanda zasu zama ƙalubale don cimma ta amfani da dabarun injunan gargajiya.Wannan sassauci a cikin siffa yana ba da damar samar da abubuwan da aka keɓance waɗanda aka keɓance da takamaiman aikace-aikace.

2 Ingantattun Kayayyakin Injini

Sintering yana haɓaka kaddarorin injiniyoyi na kayan, yana haifar da abubuwan haɗin gwiwa tare da ingantattun halayen aiki.A yayin aiwatar da sintering, ɓangarorin suna haɗuwa kuma suna ɗimbin yawa, suna haifar da ingantacciyar ƙarfi, taurin, da juriya na samfurin sintered.Hanyoyin dumama da watsa shirye-shiryen da aka sarrafa da ke cikin sintering suna ba da gudummawa ga haɓakar tsari mai yawa da haɗin kai, haɓaka cikakkiyar amincin kayan aikin gabaɗaya.

3 Abubuwan Haɗaɗɗen Material

Sintering yana ba da izini don ƙarfafa foda tare da nau'i daban-daban, yana ba da damar samar da kayan aiki tare da abubuwan da aka kera.Ta hanyar haɗa nau'ikan foda daban-daban ko haɗa abubuwan ƙari, yana yiwuwa a canza halayen kayan bisa ga takamaiman buƙatu.Wannan sassauci a cikin abun da ke ciki yana buɗe yuwuwar ƙirƙirar kayan haɓakawa tare da ingantaccen aiki, kamar gami da ƙarfi mai ƙarfi ko kayan tare da takamaiman kayan lantarki ko thermal.

4 Tasirin Kuɗi

Sintering hanya ce ta masana'anta mai tsada idan aka kwatanta da narkewar gargajiya da tsarin simintin gyare-gyare.Yin amfani da kayan foda yana rage sharar gida, kamar yadda za'a iya tattara foda mai yawa kuma a sake amfani dashi.Bugu da ƙari, tsarin sintiri yana buƙatar ƙarancin amfani da makamashi tunda yana aiki a yanayin zafi ƙasa da wurin narkewar kayan.Ƙarfin samar da abubuwan da ke kusa-tsalle-tsalle yana ƙara rage buƙatar ayyukan injiniyoyi na gaba, wanda ya haifar da ajiyar kuɗi dangane da amfani da kayan aiki, amfani da makamashi, da kuma bayan sarrafawa.

5 Samfura a Zaɓin Kayan Abu

Sintering yana ba da juzu'i a zaɓin kayan aiki, yana ɗaukar abubuwa da yawa don aikace-aikace daban-daban.Ya dace da tukwane, karafa, da abubuwan haɗaka.Daban-daban nau'ikan kayan, gami da oxides, carbides, nitrides, da gami, ana iya sarrafa su ta hanyar sintiri.Wannan faffadan daidaituwar kayan abu yana ba da damar samar da abubuwa daban-daban tare da takamaiman kaddarorin kayan, yin sintering zaɓi mai ban sha'awa ga masana'antu da yawa.

Fa'idodin Sintering a cikin hadaddun siffa, ingantattun kaddarorin inji, abubuwan da aka keɓancewa, ƙimar farashi, da juzu'in kayan aiki sun sa ya zama tsarin masana'anta mai mahimmanci a sassa daban-daban.Ta hanyar yin amfani da waɗannan fa'idodin, masana'antu za su iya samun ingantaccen samarwa, haɓaka aiki, da tanadin farashi a cikin hanyoyin sarrafa su.

Akwai sauye-sauye da yawa da suka haɗa da hadaddun sauye-sauye na jiki da na sinadarai.Jiki da sinadaran halayen a cikin foda sintering ciki har da evaporation ko evaporation na ruwa ko kwayoyin halitta, kau da adsorbed iskar gas, danniya taimako, rage surface oxides na foda barbashi, abu ƙaura, recrystallization, hatsi girma, da dai sauransu Yana da matukar muhimmanci a koyi. da kuma fahimtar ilimin sintering a matsayin furodusa.Kuma a matsayinmu na mabukaci, koyan waɗannan ilimin asali na iya ba mu damar samun kyakkyawan ra'ayi yayin zabar samfuran ƙira.

Sintering tsari ne na gargajiya kuma mai rikitarwa.Lokaci yana ci gaba, Kuma ana sabunta fasahar samarwa da kayan aikin samarwa koyaushe.Ajiye ilimin asali kuma koyi sabon ilimin ya zama dole ga ma'aikatan da ke da alaƙa da masana'antu.Domin shekaru 18 da suka gabata.HENGKOko da yaushe yana dagewa kan inganta kanta akai-akai, samar da abokan ciniki tare da samfurori masu kyau da ayyuka masu mahimmanci, taimakawa abokan ciniki da ci gaba na kowa.Muna fatan zama amintaccen abokin tarayya na dogon lokaci.

FAQs (Tambayoyin da ake yawan yi)

Wadanne kayan za a iya sinteta?

Ana iya haɗa abubuwa da yawa, gami da yumbu, karafa, da abubuwan haɗaka.Misalai sun haɗa da foda na yumbu kamar alumina da zirconia, foda na ƙarfe kamar ƙarfe dasintered bakin karfe tace, da kuma foda masu haɗaka da ke ɗauke da kayan ƙarfafawa irin su zaruruwa ko ɓarna.

Menene fa'idodin sintering idan aka kwatanta da sauran hanyoyin masana'antu?

Sintering yana ba da fa'idodi da yawa akan hanyoyin masana'antu na gargajiya.Yana ba da damar samar da abubuwan da aka haɗa tare da siffofi masu rikitarwa da ƙira masu mahimmanci, yana ba da ingantattun kayan aikin injiniya, yana ba da damar gyare-gyaren kayan haɗin gwiwar kayan aiki, yana da tsada saboda rage yawan sharar gida, kuma yana ɗaukar nau'o'in kayan aiki don aikace-aikace daban-daban.

Menene manyan aikace-aikace na sintering?

Sintering yana samun aikace-aikace a masana'antu kamar su yumbu, ƙarfe, ƙarfe na foda, kayan lantarki, da masana'anta ƙari.Ana amfani da shi don samar da fale-falen yumbura, sassan motoci, abubuwan ƙarfe, kayan aikin yankan, yumbu na lantarki, da abubuwan bugu na 3D, da sauransu.

Shin akwai iyakoki ko ƙalubale tare da sintering?

Sintering yana da wasu iyakoki da ƙalubale.Samun daidaitaccen ƙima a cikin kayan yana iya zama ƙalubale, saboda rashin daidaituwar dumama ko rarraba barbashi na iya haifar da lahani.Sarrafa haɓakar hatsi da kuma hana raguwar wuce gona da iri a yayin da ake yin shuru suma suna da mahimmanci.Bugu da ƙari, ba duk kayan da suka dace da sintering ba saboda manyan wuraren narkewa ko sake kunnawa tare da yanayin kewaye.

Menene nau'ikan fasahar sintering daban-daban?

Akwai dabaru iri-iri na sintering iri-iri, ciki har da m-state sintering, ruwa-lokaci sintering, kunna sintering, microwave sintering, matsa lamba-taimaka sintering, kazalika da musamman dabaru kamar selective Laser sintering (SLS) da electron katako sintering (EBS).Kowace dabara tana da hanyoyinta na musamman kuma an zaɓa bisa ƙayyadaddun buƙatun kayan aiki da aikace-aikacen.

Ta yaya sintering ke inganta kaddarorin kayan?

Sintering yana inganta kaddarorin kayan ta hanyar haɓaka haɗin gwiwar barbashi da ƙima.A lokacin aikin sintering, barbashi suna yin yaduwa, suna haifar da samuwar wuyan wuyansa da ƙara yawan yawa.Wannan yana haifar da ingantattun kayan aikin injiniya kamar ƙarfi, taurin, da juriya.Bugu da ƙari, sintering na iya haifar da ingantattun kayan lantarki, thermal, da sinadarai dangane da kayan da abun da ke ciki.

Za a iya sarrafa sassan da aka ƙera ko kuma a ƙara sarrafa su?

Ee, sassan da aka ƙera na iya samun ƙarin sarrafawa ko injina, idan an buƙata.Yayin da sintering zai iya cimma abubuwan da ke kusa-tsarin-net, za a iya samun wasu lokuttan da ake buƙatar ƙarin mashina ko aiwatar da aiki don cimma ƙayyadaddun abubuwan da ake so.Za'a iya amfani da hanyoyin sarrafa injina kamar niƙa, hakowa, ko niƙa don cimma ƙimar ƙarshe ko ƙarewar ƙasa.

Menene la'akari da muhalli na sintering?

Sintering gabaɗaya ana ɗaukar tsarin masana'anta da ke da alaƙa da muhalli.Yana cinye ƙarancin kuzari idan aka kwatanta da narkewa da hanyoyin simintin gyare-gyare, kuma yana rage sharar kayan abu ta hanyar barin sake amfani da foda mai yawa.Duk da haka, yana da mahimmanci a yi la'akari da tasirin muhalli na albarkatun albarkatun da aka yi amfani da su, da kuma yadda ya dace da kulawa da zubar da duk wani kayan aiki ko sharar da aka haifar yayin aikin.

Ta yaya sintering ke ba da gudummawa ga haɓaka kayan haɓakawa?

Sintering yana taka muhimmiyar rawa wajen haɓaka kayan haɓaka.Ta hanyar a hankali zaɓi da sarrafa abun da ke ciki, girman barbashi, da sigogin sintiri, yana yiwuwa a daidaita kaddarorin kayan da aka samu.Wannan yana ba da damar ƙirƙirar kayan haɓakawa tare da ƙayyadaddun halaye, kamar ƙayyadaddun kayan aiki masu ƙarfi, yumbu mai aiki, ko kayan haɗin gwiwa tare da haɗuwa na musamman na kaddarorin.

Idan kuna da wasu ƙarin tambayoyi ko kuna son tuntuɓar junaHENGKO,

da fatan za a ji daɗin tuntuɓar mu ta imel aka@hengko.com.

Za mu yi farin cikin taimaka muku da samar da kowane ƙarin bayani da kuke buƙata.

Lokacin aikawa: Agusta-14-2020